- +31(0)499-364-820

- News & Blogs

-

EnglishEN

Download leaflet

Interested in our QBind Beef PP70B leaflet?

-

Applications: Cooked sausages - eaten hot (hot dog, viena, frankfurter, breakfast sausage, grill type), Cooked sausages - cold cuts (lyoner, Pariser, Bologna, Mortadella type), Canned meats (luncheon meats, corned beef, meat spreads), Meat balls, hamburgers, fresh sausages, Fresh meat, Cooked whole muscle ham, Cooked salami (salami cotti, sucuk), Blood sausage, black pudding, blood pancake, morcilla, Nuggets, schnitzel, cordon blue, Fish ball, surimi, restructured fish Function: Bind Origin: Beef Benefits: Clean label, Texture/bite, Spreadability, Shrinkage reduction, Emulsion stabilizer (meat matrix - protein, fat, moisture), Cooking / frying yield, Sliceability / Slicing yield, Low collagen, Meat, Fat, Phosphate, Cost reduction Plasma proteins are the perfect heat setting proteins to be used in cooked meat products. Plasma does not have any functionality when it is unheated, but the moment when it is heated, plasma proteins set and firm into a stable mass. This is a non reversible process, meaning that after cooking and cooling down, the plasma keeps its firmness. Therfore, plasma is the ideal product to use in cooked hams, sausages and canned meat products where waterbinding and firmness of texture are important. Plasma has a waterbinding up to 1:15 and has good emulsification in heated solutions (1:10:10). 100% natural from bovine or porcine origin. Hydroxyproline free.

-

-

Contact one of our experts in your region

Let's connect for tailor made advice, an offer or a sample and discuss how our functional protein can optimise your product.

-

-

Application:

Plasma is available in bovine and porcine origin, in 3 forms, a 70% protein content powder, a 80% protein content powder and a concentrated liquid (frozen) of 17% protein content. Applications perfectly suited for plasma are cooked meat products in general as it is a heat setting protein. Examples of such are whole muscled and reformed hams, frankfurter sausages, canned hams and bologna's.

Plasma is perfectly soluble and therefore finds perect use for injection and tumbling. It does not affect brine viscosity. A natural protein, maybe even the closest relatable to meat. Dosage of plasma powder lays around max. 1-1,5%, without noticing any plasma flavor.

Evidence:

At the production of cooked ham and shoulders the application of plasma proteins offers benefits because of the excellent functional properties, like high solubility, and excellent gelling and water binding at heating. These properties result in the following effects in ham products:

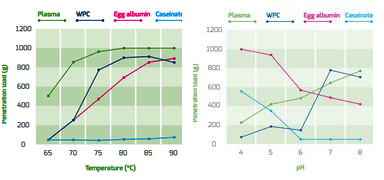

Figure 1 (Left): Influence of heating temperature on gel strength

Factor: temperature and gelling

- Relatively strong gelling of plasma protein at lower temperatures

- Plasma protein forms a stronger gel than other proteins

Source: International Food Marketing & Technology

Figure 2 (Right): Influence of pH on gel strength after heating

Factor: pH and gel strength

- different behavior of proteins

- stronger plasma protein gel at higher pH

Source: International Food Marketing & Technology

Benefits:

- Reducement of cooking loss

- Possible to reduce cost-price meat product

- Perfect applicable in pasteurized & sterilized products

- Very good emulsifying capacities in hot conditions

- Improvement of texture

- Bovine & Porcine available

- 100% natural heat setting protein

Characteristics:

- Applicable in all processes

- Clean label

- Phosphate replacement

- Meat replacement

- Cooking yield improvement

- Slicing yield improvement

- Texture/bite improvement

- Syneresis reduction

- Shrinkage reduction

- Cost price reduction

- Injectable solutions

- Low collagen